Precision Tools for Every Coating Application #

Since 1985, ROXGEN has focused on developing world-class manual spray guns, meticulously engineered and manufactured in Taiwan. Our commitment to quality is evident in every stage—from the selection of raw materials and CNC machining to the micron-level tolerances of our components. Each spray gun is designed to deliver consistent performance, reliability, and value for professionals across a wide range of industries.

Whether you are an automotive refinisher seeking a flawless finish, a furniture coating specialist prioritizing efficiency, or an artist requiring detailed control, ROXGEN offers a comprehensive lineup to meet your needs.

Automotive Spray Gun

Automotive Spray Gun

HVLP Series

HVLP Series

Mini Series

Mini Series

X Series

X Series

W-71 / W-77

W-71 / W-77

Release agents and oils spray gun

Release agents and oils spray gun

Ceramic Spray gun

Ceramic Spray gun

Long Tube Spray Gun

Long Tube Spray Gun

Manual Spray Gun Categories #

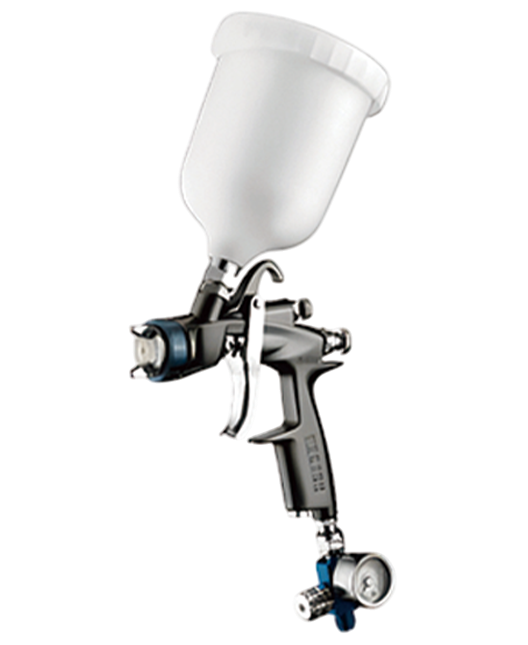

1. HVLP / LVLP High-Efficiency Spray Guns #

Key Advantages: High transfer efficiency, cost savings, eco-friendly

HVLP (High Volume Low Pressure) and LVLP (Low Volume Low Pressure) technologies are now standard for modern coating applications. ROXGEN’s high-efficiency series features proprietary air cap and nozzle designs, achieving transfer efficiency up to 65% and above at lower atomizing pressures. This results in more coating adhering to the workpiece and less lost to overspray.

- Significant Material Savings: Reduces paint waste and operational costs.

- Reduced VOC Emissions: Lowers volatile organic compound release, supporting environmental standards and technician health.

- Superior Atomization: Delivers a fine, uniform finish at low pressures, suitable for various basecoats and clearcoats.

- Ideal Applications: Automotive OEM and refinishing, wood furniture coating, hardware, and plastic finishing.

2. Conventional High-Atomization Spray Guns #

Key Advantages: Ultra-fine atomization, mirror-like finish

For those seeking a perfect, glass-like finish, conventional high-atomization spray guns remain a classic. ROXGEN’s precision manufacturing ensures micron-level fit tolerance for the nozzle, needle, and air cap, producing the finest atomized particles for a flawless surface.

- Show-Quality Finish: Achieves a mirror-smooth, high-gloss topcoat.

- Full, Uniform Pattern: Wide, even coverage with excellent ergonomics.

- Trusted Classic Technology: Preferred by veteran painters for final clearcoat applications.

- Ideal Applications: High-end automotive topcoats, high-gloss furniture, musical instruments.

3. Mini / Touch-Up Spray Guns #

Key Advantages: Precision control, lightweight, agile, ideal for repairs

ROXGEN’s mini spray guns offer the same precision as full-size models in a compact, lightweight body. They provide excellent maneuverability and control for small-area repairs, sample testing, or detailed artistic work.

- Superb Handling: Ergonomic, lightweight design reduces fatigue.

- Precise Pattern Adjustment: Engineered for detail work, capable of small, concentrated patterns.

- Versatile Use: Suitable for repairs, hobbyists, model makers, and artists.

- Ideal Applications: Automotive spot repairs, prototyping, model painting, arts and crafts.

4. Suction Feed Spray Guns #

Key Advantages: Large volume capacity, suitable for higher-viscosity materials

Suction feed spray guns use the Venturi effect to draw material from a cup below the gun, ideal for large-volume jobs or spraying higher-viscosity materials. ROXGEN’s models are built for durability and reliable atomization during high-volume work.

- Large Cup Support: Compatible with larger cups (typically 1000cc) for efficiency.

- Handles Viscous Materials: Suction action assists with thicker coatings.

- Ideal Applications: Large-area single-color painting, structural steel, railings, industrial equipment.

5. Primer Spray Guns #

Key Advantages: High flow rate, efficiency, built for heavy coatings

ROXGEN’s primer guns are designed for fast, even coverage of thick, high-viscosity primers. Larger nozzle sizes (1.6mm-2.5mm) ensure efficient application and a uniform base for subsequent coats.

- Efficient Priming: High-flow design for rapid primer application.

- Durable & Reliable: Reinforced components withstand abrasive primers.

- Uniform Atomization: Ensures a flat, even primer coat.

- Ideal Applications: Automotive surfacer primers, woodworking sealers, industrial anti-corrosion primers.

6. Airbrushes #

Key Advantages: Ultimate detail, artistic creation, fine line control

ROXGEN airbrushes are engineered for micro-atomization, enabling ultra-fine lines and smooth gradients. They are suitable for a variety of artistic and precision applications.

- Micron-Level Control: Available in dual-action or single-action models.

- Multi-Functional Use: Compatible with water-based or solvent-based paints.

- Ideal Applications: Fine art, model making, cosmetics, cake decorating.

Product Overview Table #

| Spray Gun Category | Key Advantages | Ideal Applications |

|---|---|---|

| HVLP/LVLP (X-402L/X-202L) | High transfer efficiency, eco-friendly | Automotive topcoats, wood finishing, industry |

| Middle Pressure (X-102/…) | Ultra-fine atomization, mirror-like finishes | Premium automotive, high-gloss furniture |

| Mini/Touch-Up (XF-50/X-90) | Precision, agility, detail work | Spot repairs, model painting, arts |

| Suction Feed (X-202S/…) | Large volume, handles viscous materials | Structural steel, machinery, marine |

| Primer (X-402C) | High flow, thick primers | Automotive surfacers, wood sealers, anti-corrosion |

| Airbrush (TR-GP) | Fine-line, gradient control | Illustration, model weathering, cosmetics |

Frequently Asked Questions #

Q1: How do I choose between an HVLP and a Conventional spray gun?

A: If material savings, environmental compliance, and a quality finish are priorities, choose an HVLP/LVLP gun. For the highest gloss and show-car quality, a Conventional gun is ideal.

Q2: Why use a dedicated primer gun instead of a topcoat gun?

A: Primers are thicker and require larger nozzles for efficient application. Using a topcoat gun for primer can cause clogging and poor results. A dedicated primer gun ensures proper foundation work.

Q3: What does “100% Made in Taiwan” guarantee?

A: It means strict quality control from start to finish. ROXGEN uses high-grade forged aluminum and stainless steel, with all critical parts machined in-house. Each gun is manually tested for durability and performance before shipping.

Q4: What sets ROXGEN’s mini spray guns apart?

A: ROXGEN mini guns use the same professional-grade nozzle, needle, and air cap sets as full-size models, ensuring true professional atomization and control.

Q5: How can I get replacement parts or service?

A: ROXGEN offers comprehensive after-sales support. Contact us via the website or through authorized distributors for genuine factory parts and service.

Applications #

ROXGEN manual spray guns are trusted across diverse industries:

- Car Refinish

- Transportation Industry

- Building Decoration

- Industrial Applications

- Boutique Processing

- General Consumer Goods

- Carpentry

- Decorative Painting

For further information or to discuss your specific requirements, please contact us.